0086-13662744631

0086-13662744631

sales@yihuipak.com

sales@yihuipak.com

0086-13662744631

0086-13662744631

sales@yihuipak.com

sales@yihuipak.com

YCAP2000M Dream Cap Applicator: The Strategic Engine of Smart Packaging Innovation, Redefining Efficiency and Precision in Aseptic Packaging

Time: 2025-03-07

Click: 1045 times

In today’s rapidly evolving industrial production field, automation and intelligent equipment have become key forces in enhancing production efficiency and ensuring product quality. Leveraging profound technical expertise and a spirit of innovation, our company, in collaboration with SELO MACHINERY CO., LTD, has independently developed and manufactured a groundbreaking high-end automated production equipment—the YCAP2000M Dream Cap Applicator.

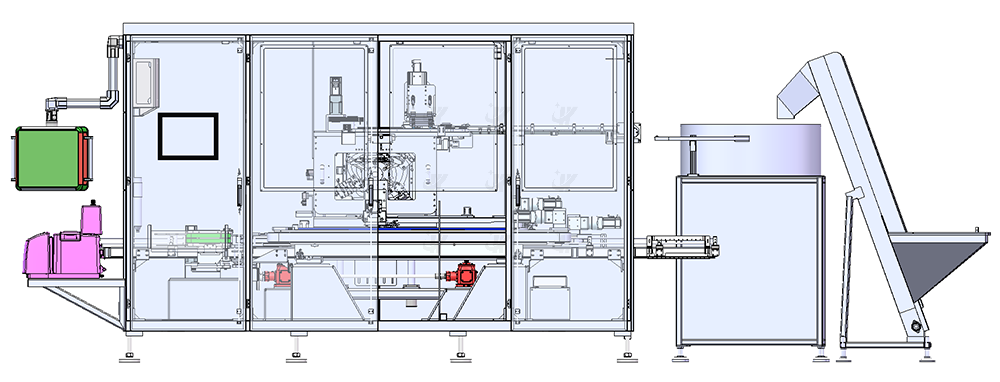

The YCAP2000M Dream Cap Applicator is a next-generation high-end automated production equipment crafted entirely from stainless steel. It integrates cutting-edge electrical components and premium auxiliary accessories from both domestic and international sources. With "full-electric servo drive technology" and a "high-precision visual recognition system" at its core, it is specifically designed for high-speed, high-precision aseptic canning applications. Delivering an "intelligent, cost-effective, and zero-contamination risk" packaging solution, it sets a new benchmark for the industry.

Main Technical Parameters:

Production Capacity: 10,000 packs/hr

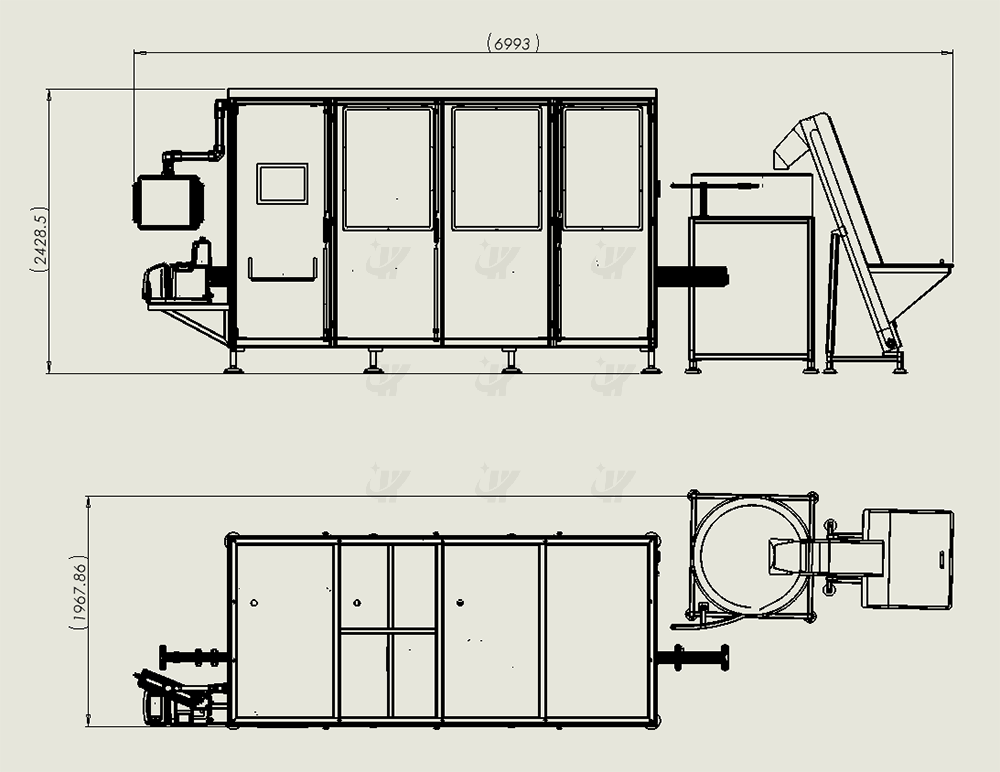

Equipment Size: 6993mm (L) × 1968mm (W) × 2429mm (H)

Weight: Approx. 3000kg

Power Input: AC 380V

Pneumatic Pressure: 0.6–0.65 MPa

Gross Power: 11.75KW

Core Advantages of the Equipment: Addressing Industry Pain Points

I. Intelligent Control for Cost Reduction and Efficiency Enhancement

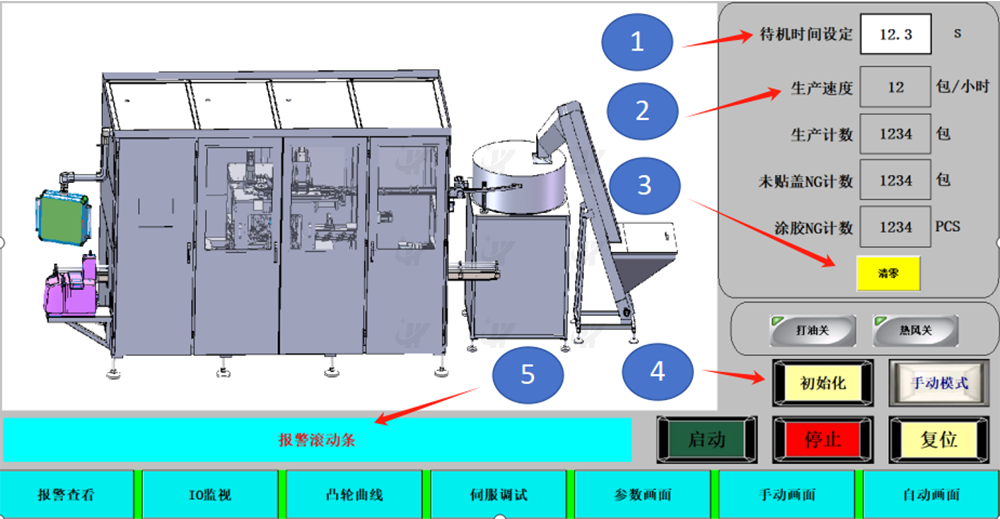

A. Equipped with an advanced intelligent control system, capable of precisely adjusting various parameters. This ensures exceptional performance stability during high-speed operation while effectively preventing production downtime and product quality issues caused by equipment failures or parameter deviations.

B. Features an intuitive and user-friendly human-machine interface (HMI), significantly reducing operational complexity and training requirements.

II. Smart Operation & Maintenance Ecosystem for Cost-Effective Lifecycle

A. Significant cost advantage achieved through optimized design and strict cost control, ensuring high-quality performance without compromising reliability. This provides customers with exceptional return on investment, truly realizing cost reduction and efficiency improvement.

III. Ultra-High Speed Capacity with Superior Drive Technology

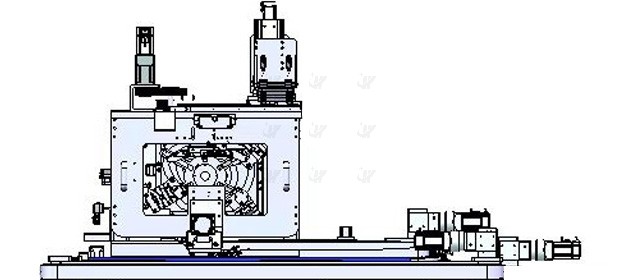

A. Three-axis motor coordination and intelligent dynamic compensation technology, utilizing two high-precision cross-linear motors and one servo motor to ensure precise control of the dispensing trajectory. This guarantees a capping accuracy error of ≤0.1mm at high speeds, effectively preventing cap misalignment or omission.

B. High efficiency with a production capacity of 10,000 packs per hour, meeting the large-scale continuous production demands of dairy and juice manufacturers.

IV. Closed-Loop Aseptic Gluing System for Sterile Packaging Ecosystem

I. Full stainless steel construction, meeting the stringent cleanliness requirements of dairy and juice filling workshops.

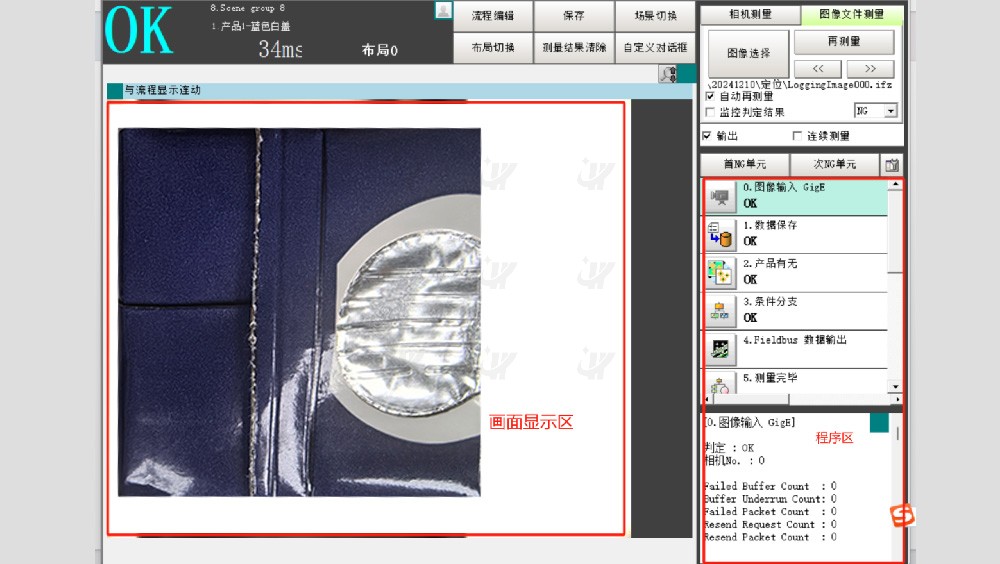

2. High-precision visual recognition system with a sealed gluing system and AI-powered real-time monitoring, ensuring precise glue application and leak-proof sealing, fully compliant with the rigorous standards of aseptic filling lines.

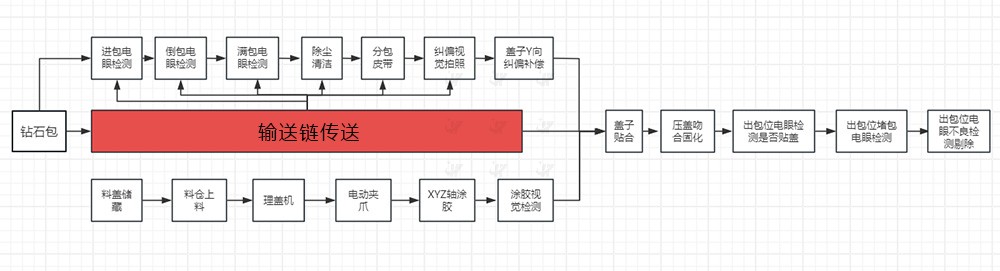

Seamlessly Integrated Processes for High Automation & Intelligence:

Partnering with YIHUI & SELO to Build a New Era of Global Smart Packaging

YIHUI & SELO, with the YCAP2000M at the core, are constructing a "device + service" integrated ecosystem:

A. Customized Solutions: Tailored process optimization plans based on customer production line characteristics to enhance equipment sustainability and production capacity density.

B. Technical Training & 24-Hour Response Service:

1. Training intelligent operation and maintenance teams for clients to reduce technical dependencies.

2. Whether for equipment maintenance, spare parts replacement, or technical consultations, we provide rapid and professional solutions to ensure the continuous and stable operation of customer production lines.

The YCAP2000M Dream Cap Applicator is not just a production tool; it is the core engine for dairy and juice companies to achieve the transformation towards "efficient, intelligent, and green" operations. YIHUI & SELO will continue to focus on foundational technological innovation, guided by customer needs, to build a new liquid food packaging ecosystem with industry partners. Together, we will drive the global dairy and juice industry into a new era of efficiency, intelligence, and sustainability.

Choosing the YCAP2000M Dream Cap Applicator means choosing an efficient, stable, and reliable production partner. Let's witness together how this innovative equipment will bring a transformation to the packaging industry and usher in a new era of smart packaging!

Video Viewing

<< Previous page

Next page >>