0086-13662744631

0086-13662744631

sales@yihuipak.com

sales@yihuipak.com

0086-13662744631

0086-13662744631

sales@yihuipak.com

sales@yihuipak.com

New Product Launch: YSA30 High-Speed Straw Applicator

Time: 2025-06-27

Click: 446 times

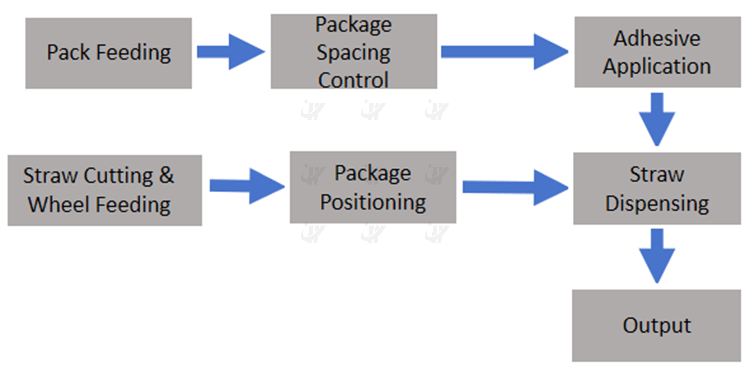

The YSA30 High-Speed Straw Applicator features a five-axis servo and asynchronous motor drive system design, which resolves the issues of synchronous errors and spare parts wear commonly found in traditional mechanical and pneumatic transmissions during high-speed operation. Its production capacity can reach up to 30,000 packs/hour, ensuring efficient and stable operation of the production line and preventing efficiency loss and material waste due to equipment malfunctions. Its working principle and process are shown in the diagram below:

The YSA30 High-Speed Straw Applicator can apply "straight straws," "U-shaped straws," and "telescopic straws" to various product specifications, including 100ml-125ml Slim, 200-250ml Standard, Slim, Medium, Fino, and Prisma aseptic packages. By controlling the straw feeding and application processes with servo drives, combined with adjustable molds and parameterized settings, the equipment can achieve product changeovers without significant structural modifications.

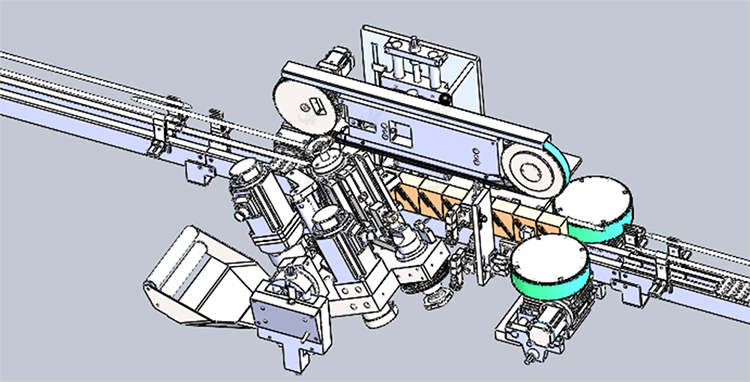

The stable operation of the equipment is based on its all-servo driven mechanical structure. Each core motion unit is controlled by independent servo motors, achieving high-precision synchronization through electronic cams. This design aims to replace traditional mechanical linkages or purely pneumatic solutions that may generate cumulative errors and wear at high speeds.

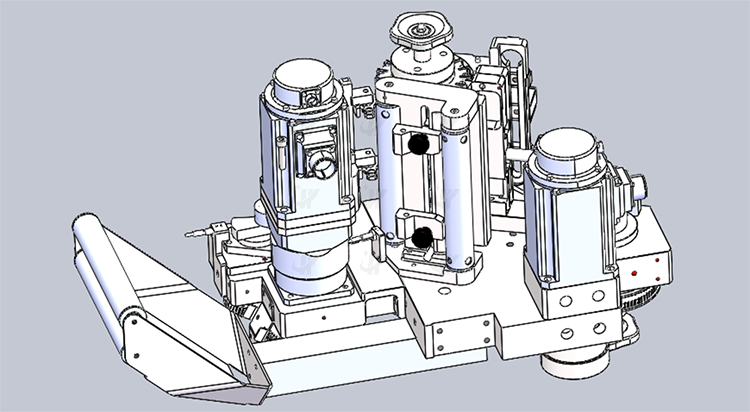

·Material Conveying and Positioning Unit: Both the pack separation and pressing units are servo-driven. Their function is to actively control the spacing between packages and perform forced positioning before application. The purpose of this design is to ensure consistent positioning of each package entering the application station, providing standardized workpieces for subsequent processes.

·Straw Application Execution Unit: This unit integrates actions such as straw feeding, dispensing, and cutting, all driven by independent servo motors. The purpose of this design is to achieve precise timing coordination of the "cut, feed, push, apply" process, thereby reducing the failure rate of straw jams or empty applications that might occur during high-speed operation.

·Hot Melt Adhesive Supply Unit: The system integrates a standard hot melt adhesive machine and is equipped with temperature and glue level monitoring functions. When an abnormality is detected, the system triggers an alarm. The purpose is to ensure the stability of the adhesive spraying process to guarantee bonding strength.

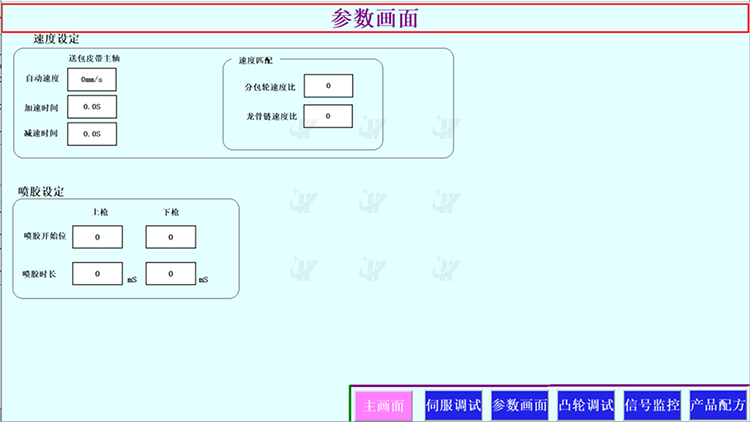

The YSA30 supports one-touch recipe recall, allowing operators to preset and store running parameters for different products. When switching products, simply select the recipe via the touchscreen to automatically load all configurations, eliminating manual adjustments and trial runs. This shortens changeover time from hours to minutes, improving production efficiency and flexibility.

Key parameters such as motor speed, acceleration/deceleration time, and adhesive spray position and duration can be digitally set in the HMI, enabling process standardization, reducing reliance on manual operation, and enhancing consistency and maintainability.

The system real-time monitors critical sensors and servo axis status. When conditions such as package jams, abnormal air pressure, or open safety doors occur, the equipment automatically stops and displays specific alarm information, facilitating rapid troubleshooting and recovery, and reducing the risk of unplanned downtime.

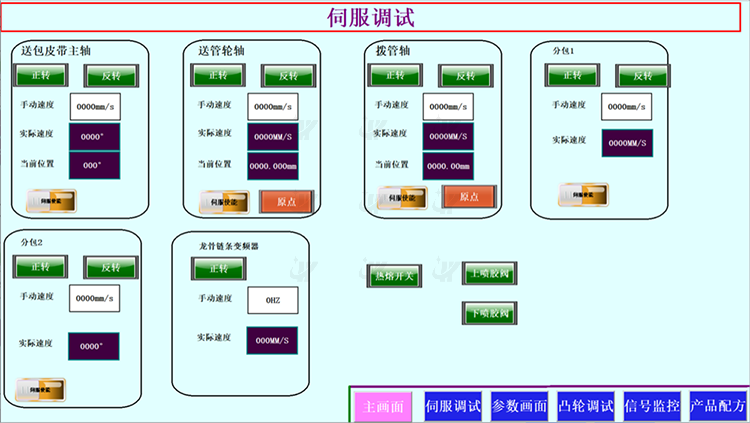

Through "forward" and "reverse" direction control and "manual speed" stepless adjustment, frame-by-frame debugging can be achieved at low speeds or even in jog mode, facilitating observation and optimization of each component's motion. Real-time display of "actual speed" and "current position," combined with the "cam debugging" function, allows for precise setting of compensation parameters to meet high-precision straw application requirements. The system supports "servo enable" and "origin" operations, facilitating servo axis homing and mode switching.

The debugging interface integrates direct control of the "hot melt switch," "upper glue valve," and "lower glue valve," supporting debugging of the hot melt adhesive system's preheating, spraying timing, and glue volume. This reduces the risk of insufficient glue and improves application quality.

The system supports real-time monitoring of servo operating parameters, promptly identifying abnormal speeds, position deviations, and alarm information. It has predictive maintenance capabilities, which helps reduce unplanned downtime and improve equipment overall equipment effectiveness (OEE).

The YSA30 High-Speed Straw Applicator provides solutions to key issues regarding stability and operational complexity for high-speed aseptic filling lines, enhancing the overall system solution.

Video Appreciation

<< Previous page

Next page >>